Avoid Outages and Failures with Proactive Substation Maintenance

When it comes to substation equipment, the importance of regular maintenance cannot be overstated. Unfortunately, this critical aspect often gets neglected until a catastrophic failure occurs. QEI understands that the backbone of a reliable electrical grid is well-maintained substation equipment and has the tools to ensure our customers stay connected.

The Cost of Neglect

Neglecting substation maintenance is comparable to ignoring the check engine light in your car. Initially, everything seems fine, but over time, minor issues can snowball into major problems. The cost of reactive maintenance far exceeds that of proactive maintenance—not just in terms of money, but also in reliability and safety.

Commonly Overlooked Areas

Several areas in substation maintenance are often neglected:

- Insulation Maintenance: Degraded insulation can lead to faults and failures.

- Relay Testing: Protective relays are vital for preventing equipment damage and ensuring safety.

- Cooling Systems: Overheating can cause significant damage to transformers and other equipment.

- Physical Security: Ensuring substations are secure from both environmental factors and unauthorized access is crucial.

QEI’s Proactive Maintenance Solutions

QEI offers comprehensive solutions to ensure that your substation equipment remains in top condition, minimizing the risk of unexpected failures. Our services include:

- Field Services: Our team can conduct a thorough inspection to identify and address potential issues before they become major problems.

- Training and Support: We provide extensive training and support to your team, ensuring they have the knowledge and skills to maintain equipment effectively.

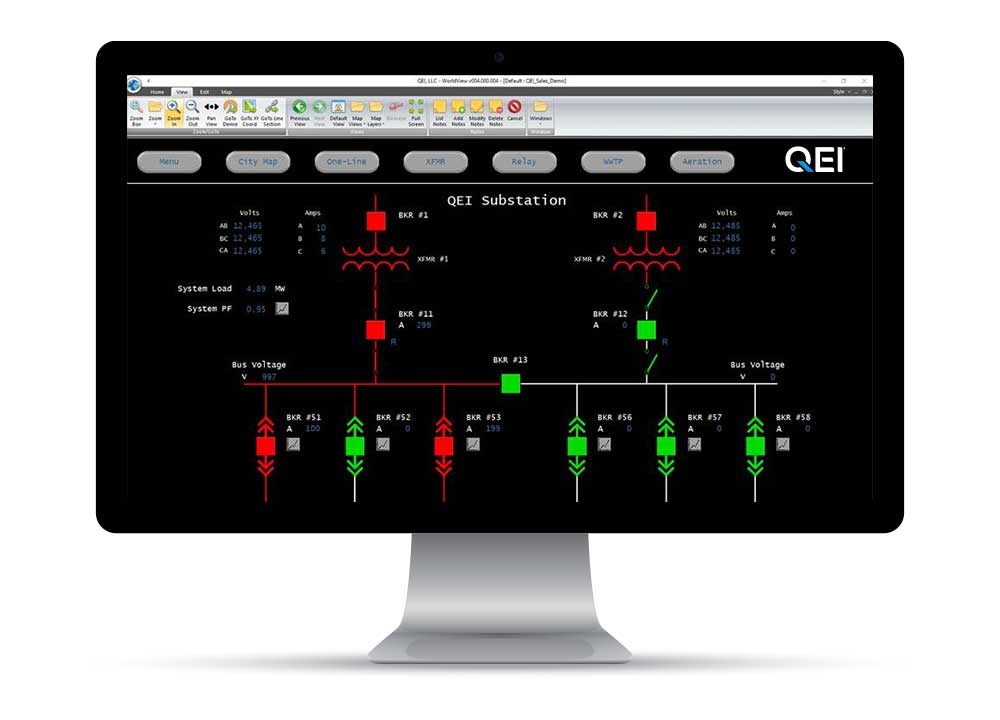

- Advanced SCADA: Utilizing Supervisory Control and Data Acquisition (SCADA) systems, you can detect issues that are not visible to the naked eye.

QSCADA and Preventative Maintenance

Incorporating QEI’s QSCADA into your substation equipment maintenance strategy can significantly enhance the reliability, efficiency, and lifespan of your equipment. By enabling real-time monitoring, data analysis, predictive maintenance, and remote diagnostics, QSCADA empowers utilities to reduce downtime and operational costs while ensuring the continuous and safe operation of electrical substations.

Real-Time Monitoring, Data Collection, and Analysis with QSCADA

QSCADA collects vast amounts of data from various sensors and devices within the substation that enable you to continuously monitor the condition and performance of your substation equipment. This real-time monitoring detects anomalies such as unusual temperature changes, voltage fluctuations, load levels, or irregular current patterns, which could indicate potential issues. QSCADA identifies trends and patterns that might signify wear and tear or imminent failure. Also, QSCADA can be configured to generate alarms for specific conditions that fall outside normal operational parameters. These alarms alert operators to potential problems, enabling them to take corrective actions before the issues escalate into major failures.

QSCADA’s Remote Diagnostics and Troubleshooting

With QSCADA, operators can perform remote diagnostics and troubleshooting. This capability is especially useful for identifying and resolving minor issues without the need for physical inspections, saving time and resources.

Improved Asset Management with QSCADA

QSCADA offers better asset management by keeping detailed records of equipment performance and maintenance history. This information is invaluable for making informed decisions about equipment upgrades, replacements, and lifecycle management.

The Benefits of Proactive Maintenance

By investing in proactive maintenance, you can:

- Enhance Reliability: Reduce the likelihood of unexpected outages and improve the overall reliability of your electrical grid.

- Extend Equipment Life: Proper maintenance can significantly extend the life of your equipment, providing better returns on your investment.

- Improve Safety: Regular maintenance reduces the risk of accidents and improves the safety of your operations.

Practical Examples of Preventative Maintenance with QSCADA

Below are some applicable examples of how preventative maintenance can work for you.

- Transformer Health Monitoring: QSCADA can monitor transformer parameters such as oil temperature, moisture content, and gas levels. Anomalies in these parameters can indicate issues like insulation breakdown or cooling system failures, prompting preemptive maintenance.

- Circuit Breaker Diagnostics: Track the number of operations, mechanical wear, and contact resistance of circuit breakers with QSCADA. Predictive maintenance can be scheduled based on this data to avoid unexpected breaker failures.

- Load Analysis: QSCADA provides detailed load analysis, helping operators identify overloading conditions and redistribute loads to prevent equipment stress and prolong the life of the substation components.

Conclusion

Substation equipment users can experience a significant improvement in reliability and a reduction in maintenance costs after implementing preventative maintenance measures. By addressing issues before they escalate, you’ll be able to avoid potential outages and extend the life of your equipment.

QEI is committed to helping you maintain the reliability and efficiency of your substation equipment. Don’t wait for a potentially catastrophic failure — contact us today to learn more about preventative maintenance with QSCADA and how we can help you keep your operations running smoothly.

For more insights on substations and substation automation, visit https://www.qeiinc.com/solutions/substation-automation/